Material

characterization

Mechanical material characterization, in particular determination of characteristic values for fiber-reinforced plastics, plastics, metals, wood, foams etc.

Possible tests according to different standards

- Tensile tests

- Print tests

- Shear tests (inner laminar and interlaminar)

- Bending tests (3-point, 4-point and mixed mode)

- CAI (Compression After Impact) tests

- Notch compression and tensile tests (OHT, OHC, FHT, FHC)

- Strength testing on joined specimens (bonded, bolted, riveted, welded, etc.)

- all tests can be realized at low or elevated temperatures

- Determination of static, cyclic and strain-rate-dependent characteristic values possible

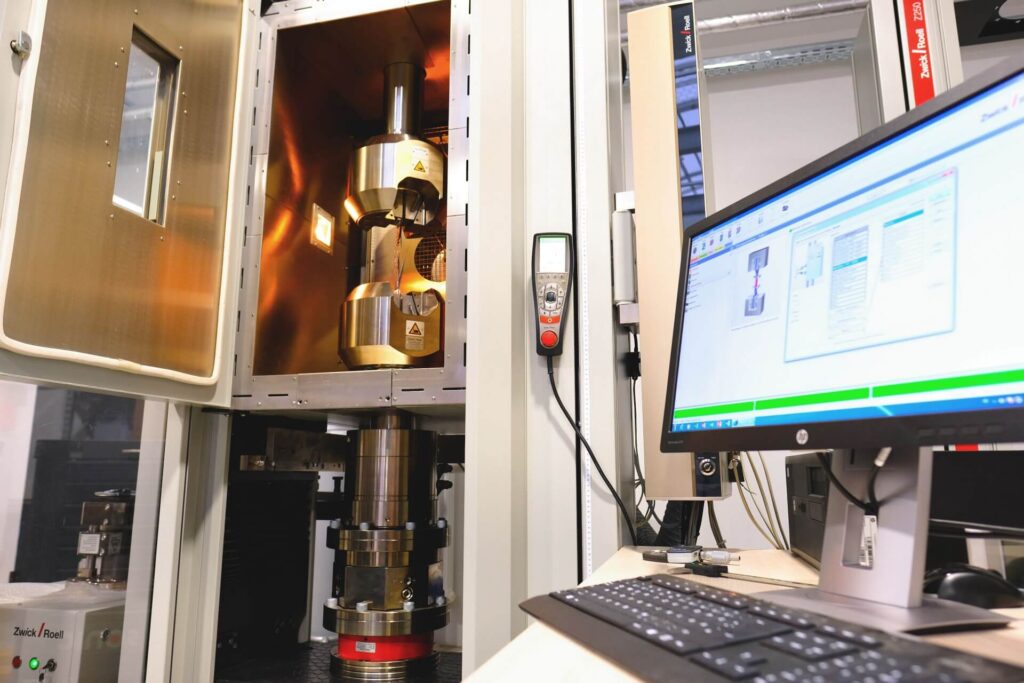

Equipment

- Zwick S250 SE

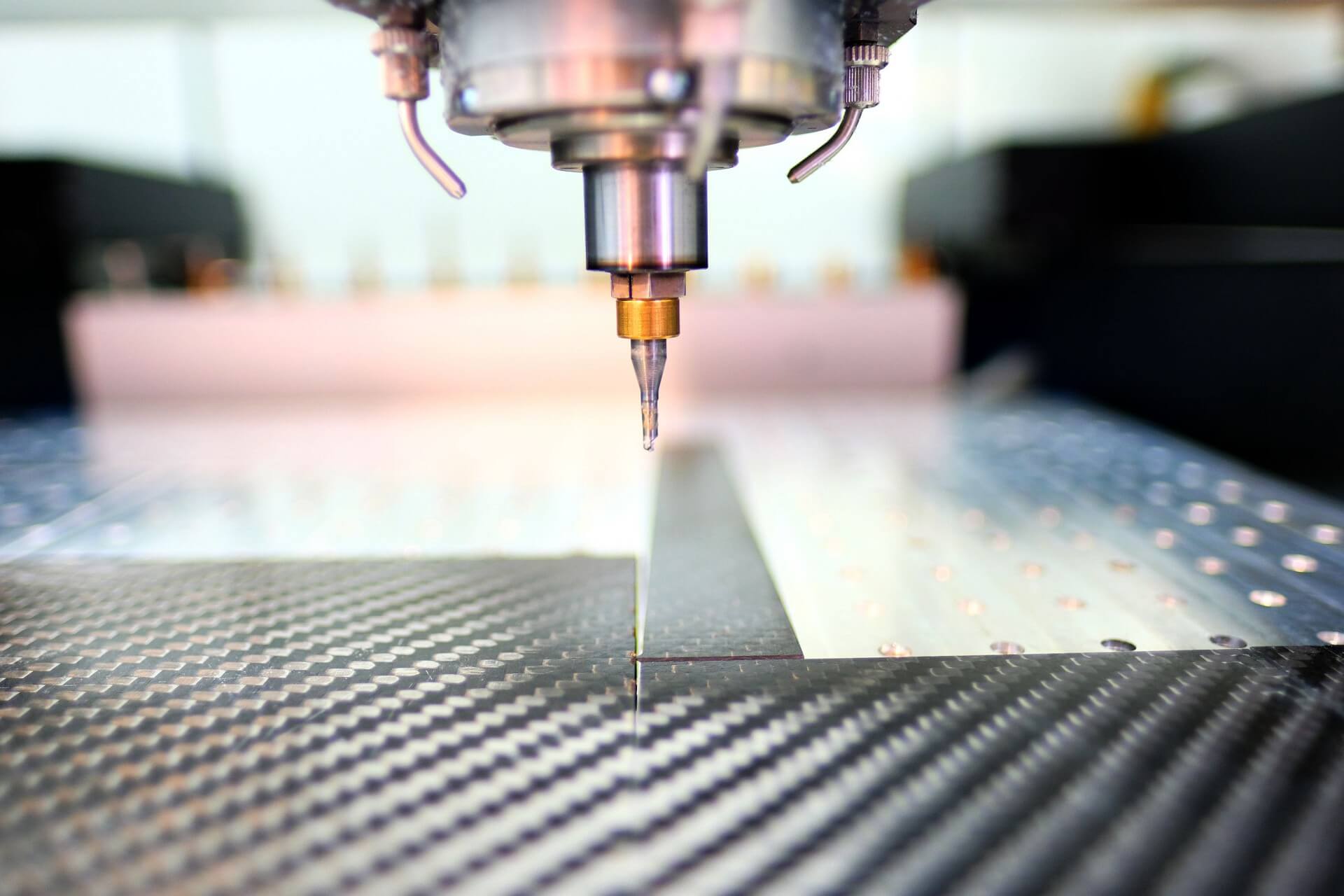

- CNC Fräse Datron M75

Test force: max. 2N to 250 kN

crosshead speed: 0.00005 – 600 mm/min

crosshead return speed: max. 1000 mm/min

travel resolution of the drive: 0.192273 nm

test temperatures: -80 to +250 °C

hydraulic and screwed test fixtures

high-precision strain measurement by means of displacement transducer MakroXtens HP

high-precision 3-axis CNC machining center

machining area: 520 mm x 650 mm x 240 mm

precise production of test specimens for material characterization