Pultrusion process

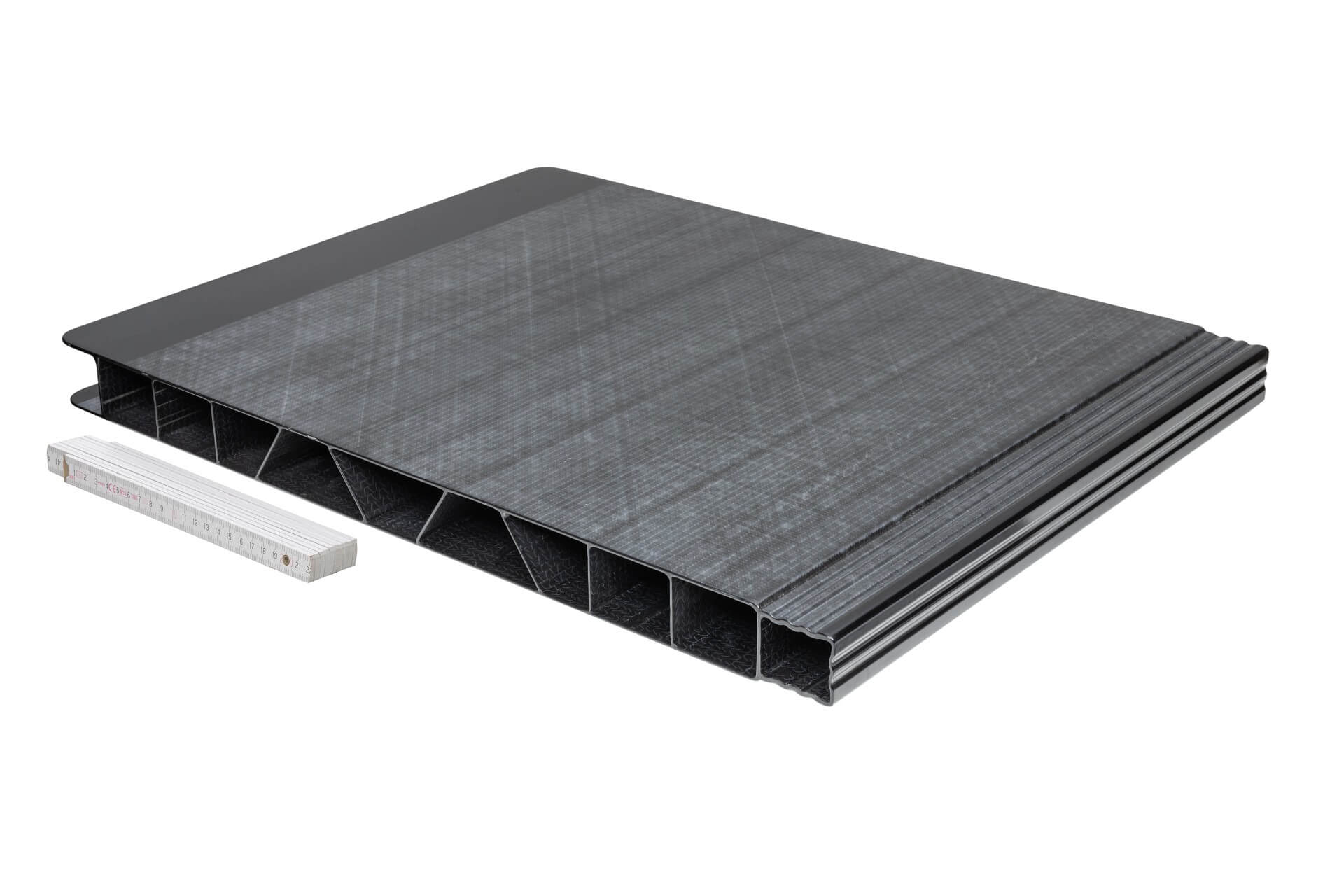

Pultrusion is a manufacturing process for the continuous and cost-efficient production of lightweight fiber composite profiles with a constant cross-section. Pultrusion profiles made of glass- or carbon-fiber-reinforced plastics – GFRP or CFRP – can be used to produce very lightweight and at the same time highly stressable frame and surface structures for various fields of application, such as support structures in rail vehicles.

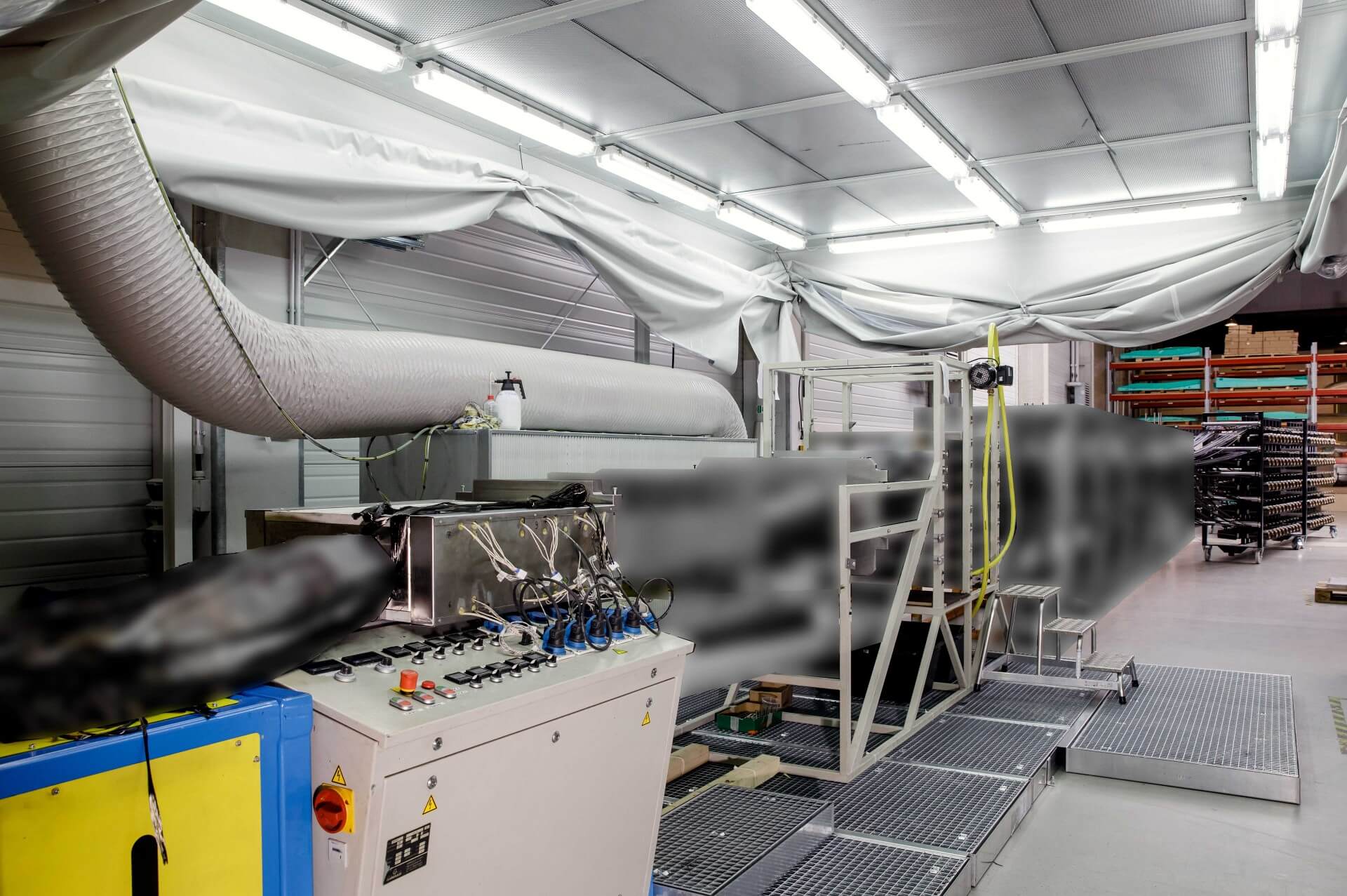

Due to this exceptionally high application and lightweight construction potential, we have built up unique know-how in the field of pultrusion for fixture and die design as well as process control. This enables us to offer our customers holistic developments – from the design and simulation of supporting structures made of pultrusion profiles for the respective application to the associated process development for technological implementation.

Our services in the field of pultrusion include:

- Process development and prototype profile production on our own pultrusion line with a maximum take-off force of 10 tons

- unique technological knowledge of pultrusion as a basis for customer-specific developments from simple round profiles with unidirectional fiber reinforcement in the longitudinal direction to complex multi-chamber profiles with multiaxial textile continuous fiber reinforcement

- Complete process development with tool design

- Support in the selection of suitable manufacturing companies for subsequent series production